In 2026, the photovoltaic industry has formally entered a new era of ”Full-Lifecycle Cleaning.” This transformation is driven by two key developments. Upstream in manufacturing, leading companies are adopting next-generation precision cleaning technologies in pursuit of ultimate environmental sustainability. Downstream in operations and maintenance (O&M), new modules integrated with self-cleaning coatings are being progressively deployed to combat harsh environments. Together, these trends elevate ”cleaning” from a peripheral maintenance task to a core strategic concern that spans the entire industry lifecycle.

Within this grand narrative, the value of a key player—specialized, intelligent physical cleaning equipment—has not diminished. On the contrary, its role has been brought into sharper focus and is being fundamentally redefined.

Firstly, new manufacturing processes are creating demand for equipment with higher standards. As PV manufacturing advances towards ”zero-carbon” goals, cleaning in the production phase is no longer merely about removing dirt. It has become a critical technology integral to achieving precision craftsmanship and environmental compliance. This necessitates cleaning equipment that delivers greater precision, reliability, and environmental compatibility to meet the stringent requirements of pollution-free, high-efficiency production. This evolution opens a new market segment for equipment providers specializing in high-end industrial cleaning solutions, driving technological upgrades.

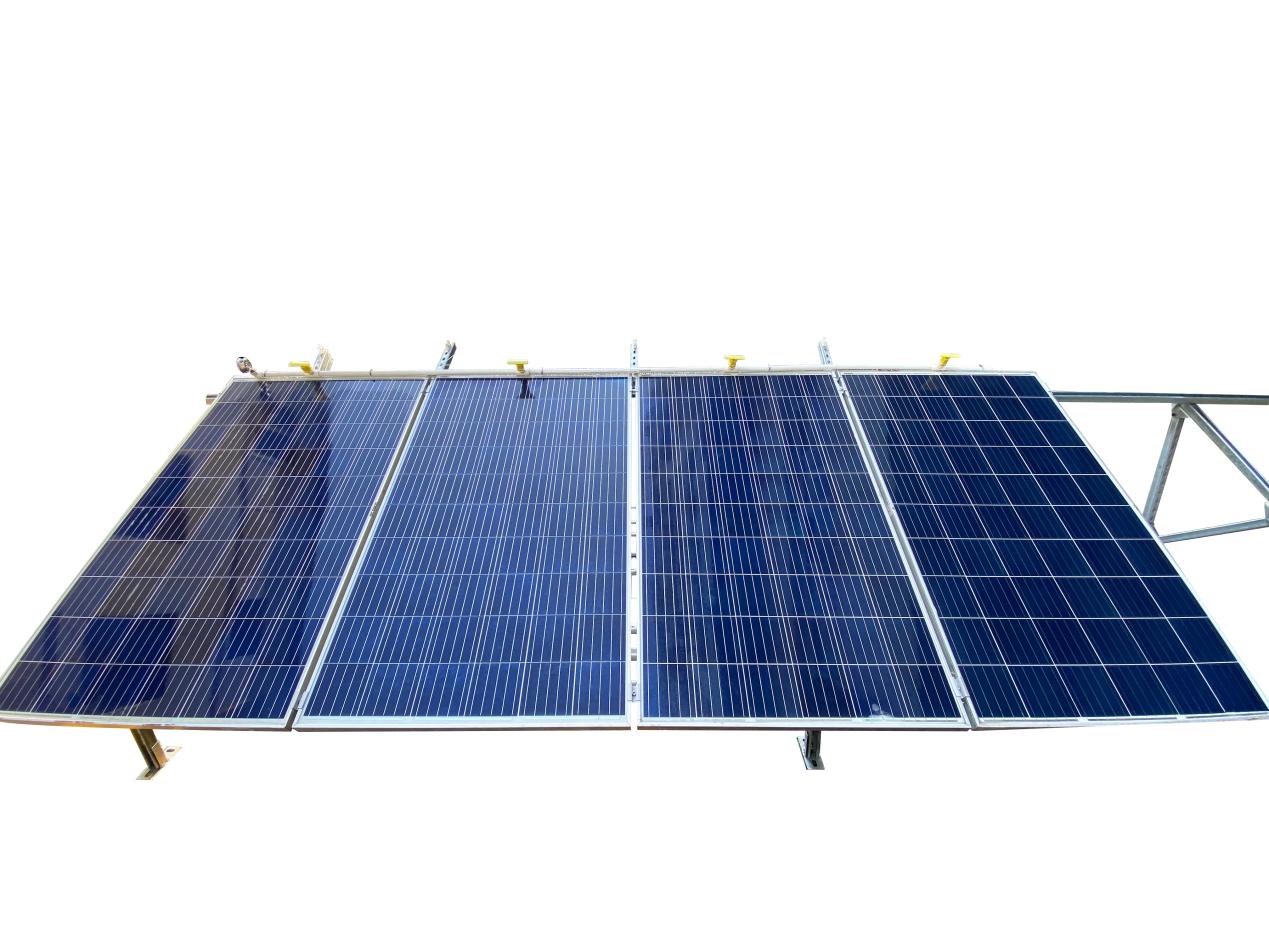

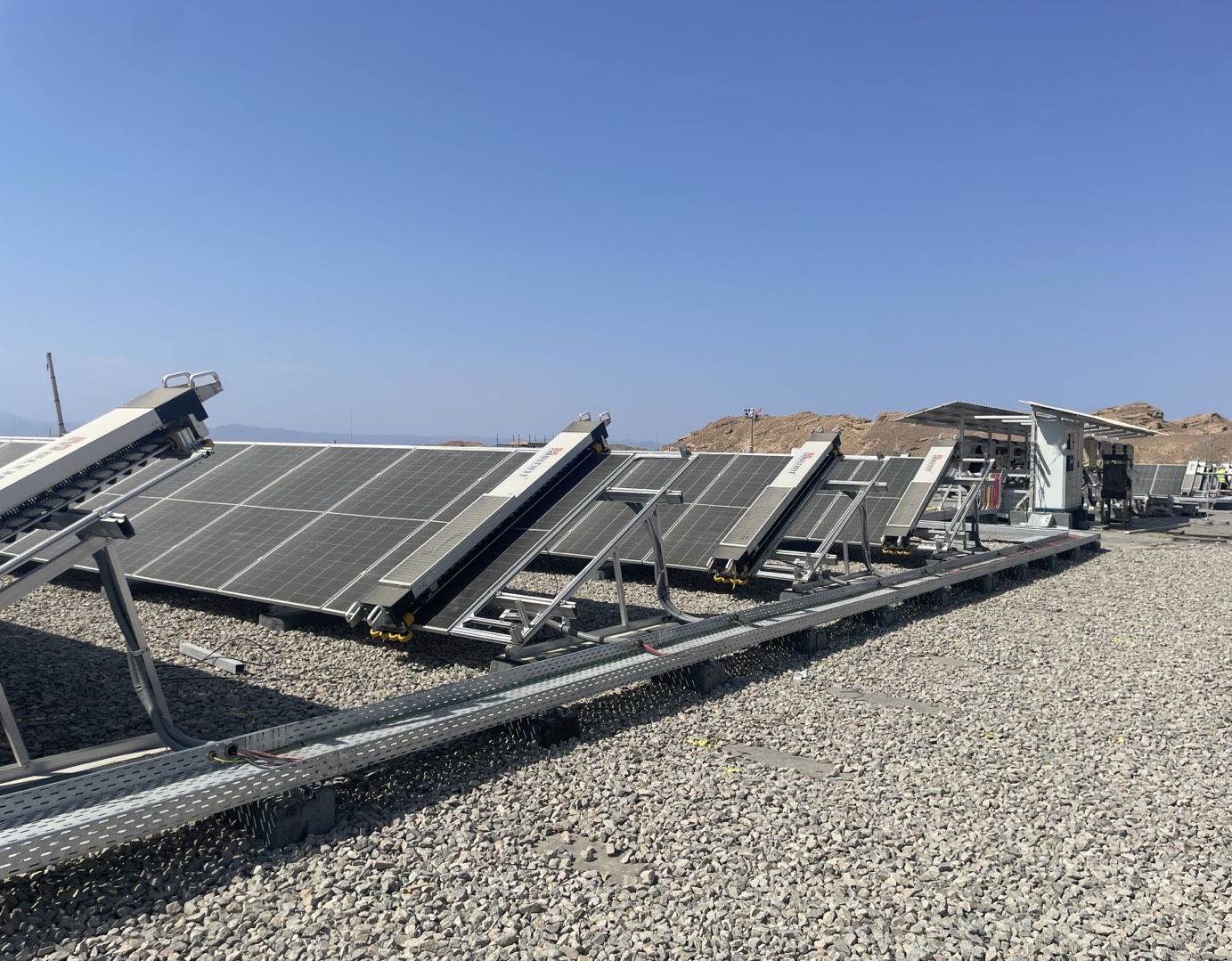

Secondly, new O&M strategies are reshaping the functional positioning of equipment. The adoption of self-cleaning coatings is altering traditional power plant maintenance models. However, these coatings are not a permanent, set-and-forget solution. For tackling stubborn contaminants, addressing localized coating failures, or performing scheduled deep maintenance, specialized physical cleaning equipment is not merely a supplement—it is an indispensable, reliable tool for ensuring the plant’s long-term optimal power generation efficiency. The role of equipment is evolving from being the ”primary cleaning labor force” to becoming a ”precision maintenance specialist,” working in tandem with active defense technologies to form a reliable, integrated O&M line of defense.

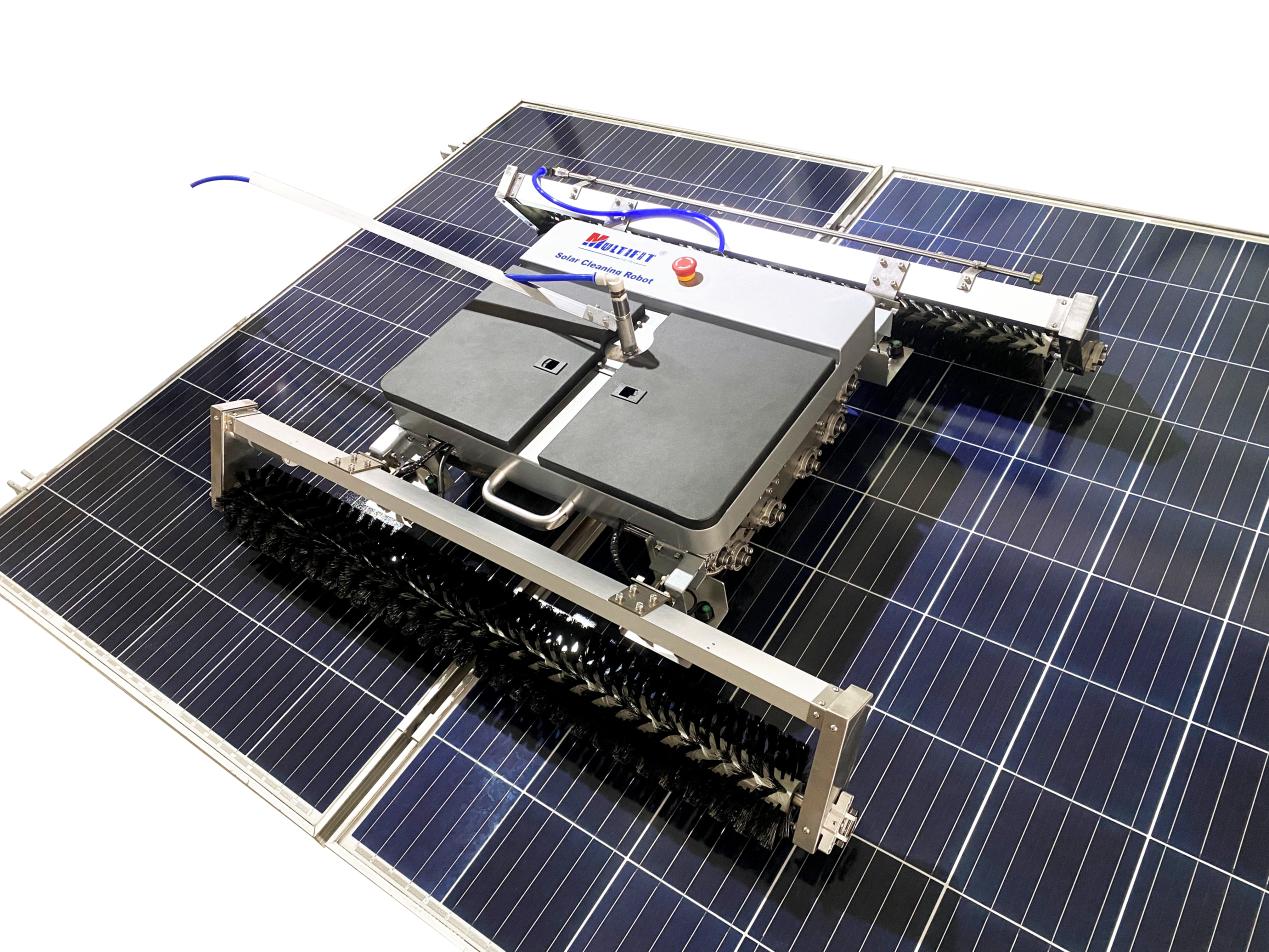

Specifically, the rise of intelligent cleaning systems, such as those developed by Multifit Solar, represents a significant leap forward. These systems transcend one-size-fits-all solutions by utilizing adaptive algorithms and modular designs. They can be precisely configured to meet the unique demands of different PV array layouts, varying installation angles, and site-specific soiling conditions. This high degree of customizability ensures optimal cleaning paths, appropriate pressure and water usage, and maximum efficiency for each unique installation, delivering a level of performance and reliability that generic equipment cannot match.

Therefore, regardless of how technology evolves, specialized and increasingly intelligent cleaning equipment remains a cornerstone solution—currently the most direct, controllable, and reliable one available. To address the complex demands of ”Full-Lifecycle Cleaning,” future equipment must evolve beyond standalone tools into integrated systems capable of deeply merging data, intelligence, and environmentally sound processes. Suppliers who can deliver panoramic cleaning solutions—spanning from precision manufacturing to intelligent O&M—are not merely selling products. They are providing the indispensable, critical support required for the sustainable development of the photovoltaic industry.

In an era of change, upholding core value; amid evolution, defining new standards—this is the mission entrusted to cleaning equipment in the new age.

Post time: Jan-07-2026